EYECON₂ IS A DIRECT IMAGING PARTICLE ANALYSER

Particle Analyses Functionality

Capture the real-time data analysis and profile of your dry powders and bulk solids with Eyecon2 particle size analyser. Troubleshoot and improve end-product goals with particle size and shape data. Adopt automated process control to drive down production cost. Non-product contact measurement minimizes risk with hazardous materials. At-line and in-line configurations allow transition from benchtop to in-line integration and evolve with your needs. EyePASS the Image analysis software now utilizes cutting edge Artificial Intelligence (AI) and Machine Learning (ML)

Advances in Machine Learning

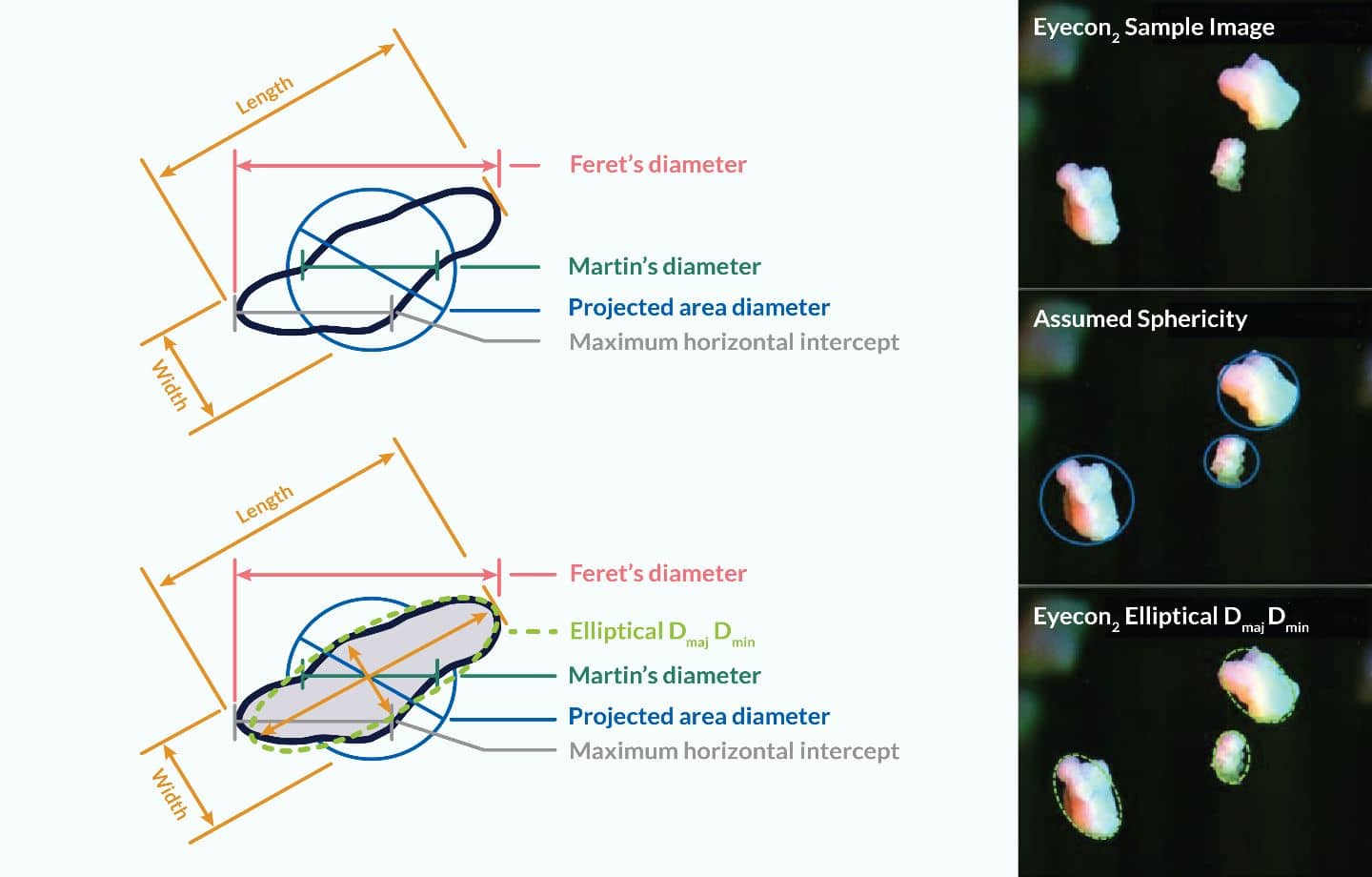

The AI upgrade transforms the versatility of the Eyecon2, vastly expanding the range of material types that can be measured in real time and drastically improves particle size and shape detection for materials that were previously unviable for image analysis. One of the primary steps performed by our image analysis software EyePASS is particle segmentation i.e., the detection and delineation of particles from the images sent by the Eyecon2. All measurements reported by the software are based on the results of the particle segmentation step.

Benefits of Machine Learning AI

Convolutional neural networks (CNN) iterate the trained images, assigns weights and biases to assorted objects in the image, differentiate one from the other and improves the feature of interest extraction from new unseen image data. This means EyePASS V 3.0 with ML image analysis unlocks the full power of particle size and shape analysis. ML image analysis negates difficulties with the traditional computer vision constraints of illumination and classification of materials with light absorption or light reflective properties. i.e dark materials, reflective materials etc. can now be measured for particle size distribution.

Technical Specifications

WHAT ARE THE BIGGEST BENEFITS?

Making particle size analysis highly efficient

Capture the real-time data analysis of your bulk powder processes automatically with our powder and bulk solid particle size analyzer. Troubleshoot and improve end-product goals with particle size and shape data. Adopt automated process control to drive down production cost. Non-product contact automation minimises risk with hazardous materials.

WHAT ARE THE BIGGEST BENEFITS?

Seize intelligent innovation

Manufacturers are leveraging more data into operations by embedding intelligent devices to increase functionality. Eyecon2 is Pharma 4.0 ready and compatible with the connected devices mantra of the Internet of Things. Using direct image analysis, our particle size analyzer can deliver more efficiency and accuracy than laser diffraction technology to measure particles.

ADAPTIVE TECHNOLOGY

Operational flexibility

Eyecon2 particle analyser can be implemented anywhere powders flow. In-line, non-product contact measurement for both Batch and Continuous processes, removing the need for sampling. Optimise product transfer and scale-up, Eyecon2 can follow and define the journey from lab to pilot to production scale, saving time and cost.

TAKING EFFICACY FURTHER

Build quality control into the process

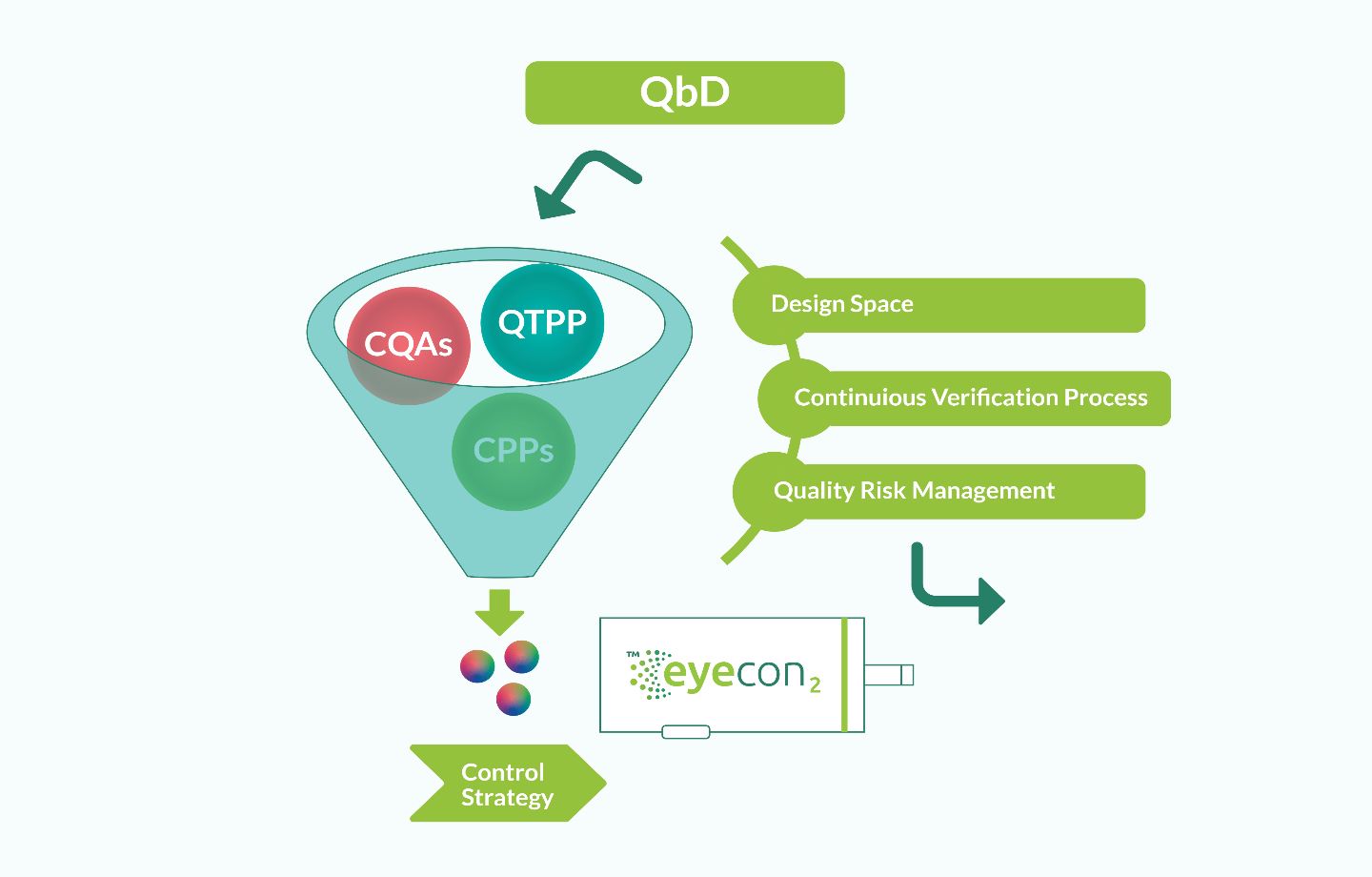

Eyecon2 underpins QbD by affording the ability to control and predict critical quality attributes (CQAs). Knowledge of particle size and shape reveals the functional relationships linking material attributes and critical process parameters (CPPs). Eyecon2 is an enabler of Continuous Process Verification.