Sensi+

Natural gas contaminants measurement made easy

The next generation single analyzer solution for natural gas contaminants

Sensi+™

Natural gas quality monitoring

Sensi+, GLA533-NG model, detects simultaneously multiple gas contaminants in natural gas. It provides continuous measurements of H2S, H2O and CO2 for custody transfer, tariff compliance, and process monitoring.

A single, compact analyzer using ABB’s proven laser-based technology providing accurate measurement and facilitating fast response time for quick actions to process upsets.

Overview

The next generation single analyzer solution for multiple natural gas contaminants

The Sensi+ GLA533-NG model is specifically designed for natural gas contaminant monitoring by targeting H2S, H2O and CO2. Real-time monitoring of contaminant levels allows triggering of threshold alarms to redirect contaminated streams that would otherwise compromise safety and operational yield.

Sensi+ offers a simple and comprehensive user interface with AnalyzerExpert™ features for increased information and user experience that provide expert actions and insights directly from your device.

For over 15 years, ABB’s Integrated Cavity Output Spectroscopy (ICOS) laser absorption technology has been at the core of the world’s most reliable gas analyzers used for applications requiring highest overall performance. Advanced spectroscopic analyses provide highest accuracy, precision, sensitivity, and reliability.

Advantages of ICOS technology

• Fast response time to variations and quick refreshment rate on measurement

• Minimizes cross-interferences using high-resolution diode laser absorption technology, low pressure, and data analytics

• Reduced cost of ownership: The sample is directly measured without conditioning and the design reduces the use of consumables

• Low sample flow, lowering the environmental impact and financial loss due to venting of gas

• No need for periodic calibration

• Internal performance metrics for asset health monitoring

Features

Thoughtfully designed with the user in mind

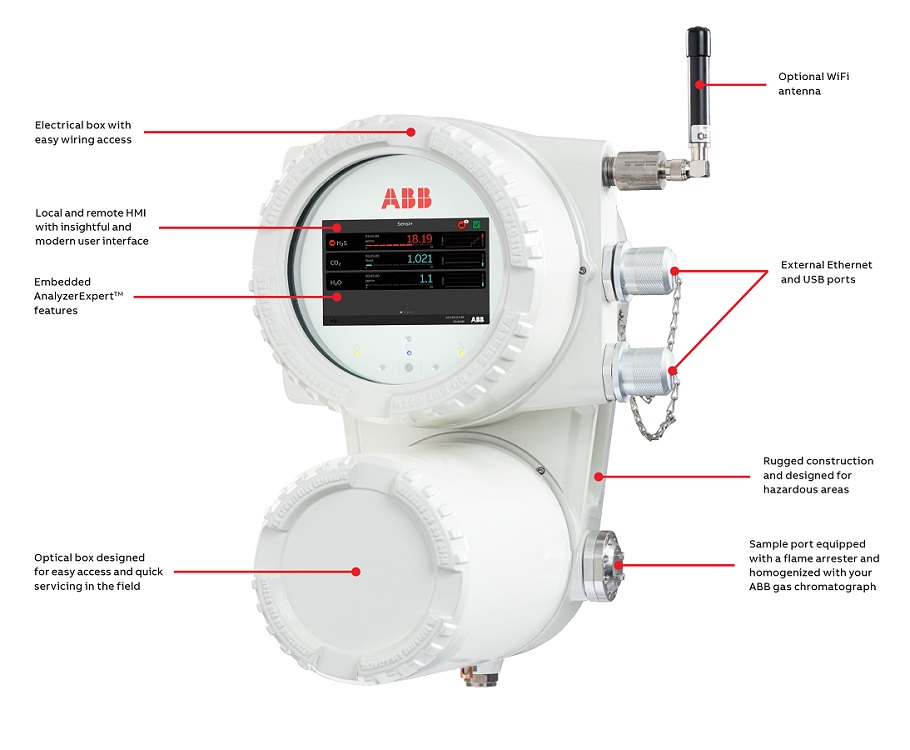

Sensi+, the single, compact analyzer based on one technology, multiplexed laser absorption spectroscopy, brings all the advantages of laser technology, saves space, and removes the need for multiple analyzers. It also simplifies deployment, operation, and service without compromising performance.

Easy installation and commissioning for hazardous areas

With flame-proof and dual-seal design, the hazardous area compliant analyzer necessitates only a simple wallmount installation and process tie-in with no complex purging system.

Needing nofield calibration, a simple validation in the field can be done and the analyzer is ready to deliver fast and reliable measurements.

User interface

Intuitive and insightful user interface on a modern software platform

The analyzer provides state of the art user interfaces both on local and remote access for quick and in-depth information.

Local Human-Machine Interface (HMI)

Sensi+ is equipped with a 7-inch screen, three informational LEDs and a gesture control system. The local HMI provides multiple views for detailed information:

• Measurement’s screen

• Alarms screen

• Diagnostics and Advanced diagnostics

• System information

Gesture Control

The local HMI is a read-only user interface (UI) and navigation is made through a gesture controller. The user can navigate through the multiple software pages by passing hand in front of the Gesture detector below the screen.

Remote HMI

The remote HMI is a HTML based UI that provides in depth information and configuration without the need of proprietary software. The remote HMI provides multiple access and menus such as:

• Measurement Screen

• Settings and configurations of gas parameters, physical interfaces, and general parameters

• Alarms display, acknowledgement, and information

• Process Events

• Reports and export of historical data

• Systems information